Products range from fuel floats and bumpers to spa cushions and parts for theme parks.

Foam injection molding near me.

Custom plastic injection molding specializing in small to large parts including structural foam molds and gas assist molds.

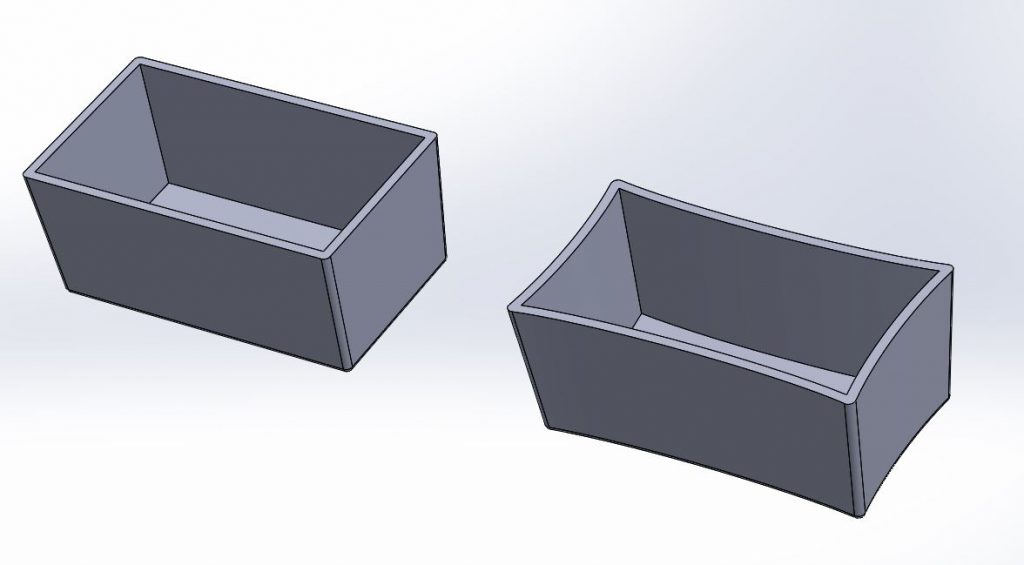

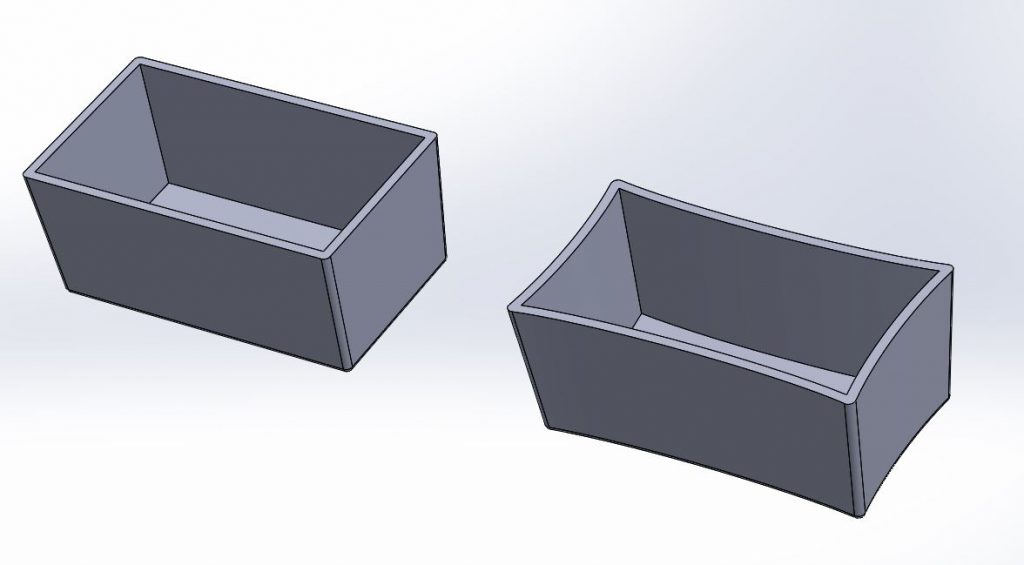

Structural foam molding is a process where the addition of a blowing agent and modification of process parameters creates a sandwich construction that has a solid skin on the outer layers and a foam core in center.

We support both brand name and niche manufacturers in creating one of a kind products using our unique eva foam technology.

Box 129 butler in 46721 map it.

We mold urethane elastomers rigid semi rigid self skinning and flexible foam.

Foam creations is the leading north american company that specializes in closed cell foam injection molding for a wide array of products.

We use but are not limited to urethane elastomers rigid semi rigid self skinning and flexible foams.

Structural foam molding process.

The process starts with injection holes size of a dime strategically drilled to lift and restore sunken concrete.

Like us on.

Xcentric custom injection molding services include the rapid delivery of prototype and low volume production components.

Our attention to detail competitive pricing and customer.

Fmi can mold all of your rim project needs.

Specialty molding fmi utilizes reaction injection molding casting and foam in place.

Utilizing reaction injection molding rim casting and foam in place foam molders inc.

In the structural foam molding process a blowing agent creates a cellular structure while a rigid.

Direct injection expanded foam molding is also known as injection molded foam and it s used to create soft foam products from a complex base resin made from an ethylene and polyolefin elastomer.

Structural foam molding is an injection process that utilizes a foaming agent that mixes with a base resin in the polymer melt before injected into the mold.

At the other end of the spectrum we frequently produce plastic parts for customers needing a few.

Polyurethane foam is injected into the holes causing a chemical reaction to fill uneven space under the slab.

Because of our streamlined production processes we typically deliver first articles in less than 13 business days and for simple expedited projects in as little as five days.

They become very rigid but are really easy to use and cure and can be used as a lightweight casting or filling material.

Polyfoam corporation can design and manufacture thermal and cushion packaging soluitons materials for construction and plastic and foam products.